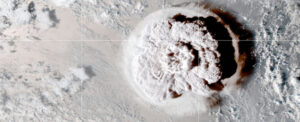

(Left) Ganoderma lucidum (rishi) grown in aluminum trays with clear plastic lids, (Middle) Large pad of Ganoderma lucidum (rishi) collected by peeling, (Right) Mycelium pad after collection and rinsing of residual growth medium. credit: Scientific fields: Biotechnological design (2024). DOI: 10.1017/btd.2024.6

× near

(Left) Ganoderma lucidum (rishi) grown in aluminum trays with clear plastic lids, (Middle) Large pad of Ganoderma lucidum (rishi) collected by peeling, (Right) Mycelium pad after collection and rinsing of residual growth medium. credit: Scientific fields: Biotechnological design (2024). DOI: 10.1017/btd.2024.6

As fashion designers look for alternatives to leather, growing mycelium or fungus-based “leather” substitutes using a new paste medium has opened up the possibility of growing this bio-derived material more quickly and making it easier to cultivate.

Researchers investigating how to grow and culture mycelium skin more efficiently tested their hypotheses by growing and harvesting mycelium skin mats using a new paste of their own design as a substrate. Their findings are published in Scientific fields: Biotechnological design.

Mycelium materials offer a low-cost and environmentally sustainable alternative to some petroleum-based materials and a more sustainable and ethical alternative to animal-derived leather. They can be grown on a wide variety of agricultural and industrial organic wastes or side streams.

With greater distribution and scale-up of production, these products have the potential to become more economically viable than established traditional materials. They can also be optimized to meet user requirements.

The researchers investigated the compatibility of mushrooms for the purpose of developing skin pads using two types of mushrooms: Ganoderma lucidum (reishi), a medicinal mushroom widely used in biodesign; and Pleurotus djamor (pink oyster), a gourmet mushroom that tends to quickly colonize the substrate and enter the fruiting stage – meaning it quickly produces mushroom fruiting bodies.

By carefully formulating a new paste substrate for the mushrooms to grow in, the researchers sought to improve nutrient availability to the mushrooms; enable their scalability; and streamlining their cultivation processes.

Different species of mushrooms have their own substrate preferences, which means that an important part of growing mushrooms – and mycelium skin – involves matching the mushrooms to the best substrate available. Common substrates include straw, coffee grounds and manure.

Tensile Testing of Micelle Samples Using Mxmoonfree Digital Force Gauge 500N. credit: Scientific fields: Biotechnological design (2024). DOI: 10.1017/btd.2024.6

× near

Tensile Testing of Micelle Samples Using Mxmoonfree Digital Force Gauge 500N. credit: Scientific fields: Biotechnological design (2024). DOI: 10.1017/btd.2024.6

Mycelial skin is produced by growing the fungus as a biological tissue or support on a liquid or solid substrate or as fungal biomass in submerged liquid fermentation. Solid state fermentation offers superior growth conditions; however, surface fermentation in a liquid state allows easier collection of mycelial mats, although growth rates are slower due to lower oxygen levels. Finally, liquid fermentation gives improved yields, but the product must be further manipulated to obtain a mycelial support.

In response to these challenges, researchers developed a new cultivation method based on a paste-like substrate that offers the advantages of high nutrient content as well as small nutrient particle size, aiding nutrient absorption.

The researchers found that using this particular paste, they were able to grow thicker mycelial mats in a shorter period of time compared to growth on nutrient-enriched agar or liquid culture. Moreover, additional benefits of this growing method became apparent during the harvest stage, as the mats became strong enough to be peeled without the need to cut the leaf.

Lead study author Asia Crawford from the University of Colorado in the United States said: “As our world looks for sustainable alternatives to traditional materials, there is growing interest in using living organisms to produce biodegradable substitutes for materials with low environmental impact – such as micellar leather, which is an ecological alternative to leather.

“The intensive processing required to transform leather into traditional leather comes at a high cost to the environment. In addition, petrochemical alternatives such as artificial leather, which are becoming increasingly popular in response to the challenges of animal skin production and the associated ethical issues, also have significant environmental impacts associated with fossil fuel extraction, long degradation periods and potential risks of off-gassing Developing better alternatives is critical in today’s ecologically fragile world.

“Biodesign methods such as those explored in our study contribute to the development of high-quality, scalable, biodegradable material alternatives. These, in turn, have the potential to address the environmental challenges of high textile consumption. Indeed, the flexible nature of pure mycelial mats is a fascinating potential substitute for nonwoven materials such as animal-derived leather and alternatives to petroleum-based synthetic leather.

“As researchers, we have a responsibility to continue developing better materials in response to the climate crisis, which is what the research is all about.”

More info:

Assia Crawford et al, Cultivation of leather with mycelium: a paste substrate approach with post-treatments, Scientific fields: Biotechnological design (2024). DOI: 10.1017/btd.2024.6